Your conveyor system literally keeps your production line running. When your conveyor system is in good working condition, it’s a key part of keeping your whole plant on top of production and shipping deadlines, quotas, etc. When it’s not…well, it can lead to one of the worst nightmares a plant manager or engineer can face: unscheduled downtime.

We all know some downtime is a necessary evil. Equipment just wears out eventually. Parts break. Connections loosen. Belts corrode or abrade and need to be replaced. It’s inevitable. The real key is making sure it’s not a surprise. And with proper planning, you can make sure it isn’t.

We believe there are two main components in that planning: a solid conveyor maintenance program, and an adequate inventory of replacement conveyor parts.

Your routine daily maintenance is as simple as looking and listening. Look for signs of damage or wear or misalignment. And listen for grinding or rubbing that can indicate problem areas to inspect more closely. Monthly, plan for a deeper dive – check belt tension, drive chains, shaft alignment, oil levels, chains and fasteners. Lubricate, adjust and tighten as needed. Semi-annually, make an even more thorough inspection of motors, shafts and bearings. And once a year, be prepared to remove belts entirely and check for needed maintenance. Planning for and executing these inspections in advance can significantly reduce the risk of unplanned downtime.

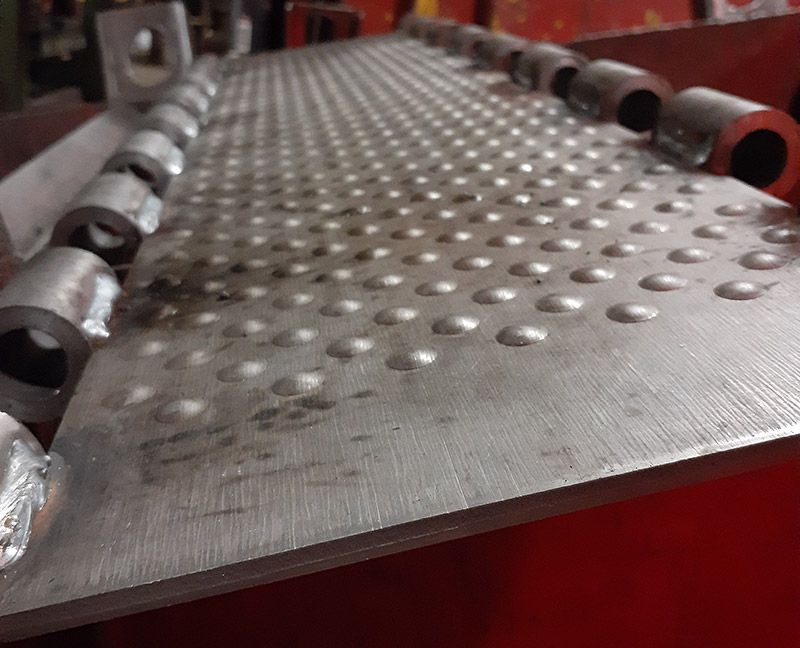

The second key component of a good maintenance plan is making sure you have the needed parts on hand. The only thing that’s worse than having your line unexpectedly shut down is finding out that you have a long wait to get the parts you need. Your conveyor belts are comprised of dozens of parts — side bars, roller block assemblies, connecting pins, chain bushings, and more — and that’s just one element of your conveyor system. Include the parts for head and tail assemblies and the total number of parts in your conveyor system is probably in the hundreds. And all it takes is one of those to break down to bring your line to a halt. Fortunately, many of these parts can be easily inventoried so you have them on hand when your regular inspections reveal a need. Call us to discuss how we can help you build a customized inventory of parts that can keep your conveyors moving.

As always, our engineers are ready to help you with any of your conveyor system needs. We can help you with everything from custom conveyor designs to maintenance training that helps your team keep your line up and running. Don’t hesitate to reach out to us with any of your questions — planned or unplanned!